Ana amfani da na'urorin compressor na iska na OPPAIR PM VSD, a matsayin kayan aiki masu inganci da aminci na matse iska, a fannoni daban-daban na samar da masana'antu. Don biyan takamaiman buƙatun samarwa, daidaita sigogin matse iska mai juyawa yana da mahimmanci. Wannan labarin zai yi cikakken bayani kan yadda ake daidaita sigogin mai amfani da na'urar compressor na iska na PM VSD don taimaka muku wajen aiki da kuma kula da na'urar compressor ɗinku.

I. Ka'idojin Asali na SukuroriIskaMatsewa

Na'urar matse sukurori galibi tana ƙunshe da na'urori biyu masu layi ɗaya, waɗanda ke haɗa na'urori maza da mata. Na'urar matse ta namiji ita ce na'urar matsewa mai aiki, kuma na'urar matse ta mace ita ce na'urar matsewa mai aiki. Na'urar matse ta namiji tana jujjuya na'urar matse ta mace, tana kammala tsarin shigar iska da matsewa. Wannan tsari yana ba da fa'idodi na inganci mai yawa, ingantaccen aminci, da kuma ikon samar da matsin lamba mai ƙarfi.

II. Muhimmancin Daidaita Sigogi na Mai Amfani

Sigogi masu amfani da na'urar kwampreso sukurori sun haɗa da matsin iska, kwararar iska, da saurin mota. Daidaita waɗannan sigogi kai tsaye yana shafar aiki da ingancin na'urar kwampreso. Daidaita sigogi masu kyau na iya inganta ingancin na'urar kwampreso, rage yawan amfani da makamashi, da kuma tsawaita rayuwar kayan aiki. Saboda haka, ƙwarewa a cikin hanyar daidaita sigogi masu dacewa yana da mahimmanci ga masu amfani.

III. Hanyoyin Daidaita Sigogi don Matsewar Iskar Sukuri

Daidaita ma'auni don matse iskar sukurori ya dogara da takamaiman samfurin kayan aiki da amfaninsu. Gabaɗaya, ana buƙatar matakai masu zuwa:

1. Da farko, duba na'urar sanyaya iska. Duba ko matsi uku na yau da kullun ne: matsin lamba na shiga, matsin lamba na fita, da matsin lamba na fitar da hayaki. Duba ko matakin mai yana cikin matsakaicin iyaka.

2. Bayan tabbatar da cewa injin yana aiki yadda ya kamata, da farko saita kuma gyara sigogin akwatin sarrafawa. Kayyade wurin saita matsin lamba bisa ga ainihin amfani da iska sannan ka shigar da shi cikin akwatin sarrafawa.

3. Daidaita matsin lamba da injin ya yi. Hanyar daidaitawa gabaɗaya ita ce a fara rage matsin lamba zuwa ƙimar da aka saita (yawanci ana saita tsakanin sandunan 7.5 da 8), sannan a hankali a ƙara matsin lamba don lura da yanayin aikin injin.

4. Daidaita zafin fitar da iska daga injin: Idan fitar da iskar ta yi zafi sosai, za ka iya rage zafin fitar da iskar ta hanyar daidaita sigogi kamar zafin shigar iska daga injin, saurin kwararar ruwan sanyaya na injin, da kuma saurin kwararar ruwan sanyaya na injin mai.

IV. Gargaɗin Daidaita Sigogi

- Kafin a daidaita sigogi, a tabbatar an fahimci halayen aikin kayan aiki da ƙayyadaddun aikinsu don tabbatar da aminci da ingancin tsarin daidaitawa.

- A lokacin gyare-gyare, a kula da yanayin aikin kayan aiki da canje-canje a cikin sigogi daban-daban, sannan a magance duk wata matsala cikin gaggawa.

- Bayan an kammala gyare-gyare, a lura kuma a gwada kayan aikin na ɗan lokaci don tabbatar da cewa gyare-gyaren sigogi sun cimma sakamakon da aka nufa.

- Yi gyare-gyare da gyara kayan aiki akai-akai domin tabbatar da cewa kayan aikin sun yi aiki yadda ya kamata kuma sun yi aiki yadda ya kamata.

- Idan wani matsala ta faru a kayan aiki ko kuma wata matsala ta faru, nan da nan a rufe shi domin a duba shi domin a guji ƙarin lalacewa.

- A lokacin aiki da kulawa, a kula da tsaftar muhalli sannan a kiyaye tsafta da aminci a wurin aiki.

- A bi dokoki, ƙa'idoji, da ƙa'idodi masu dacewa don tabbatar da cewa amincin kayan aikin da aikin muhalli ya cika buƙatun.

8. Ana ba da shawarar ƙwararrun ma'aikata su yi gyare-gyare ga muhimman kayan aiki da mahimman sigogi don tabbatar da aminci da kwanciyar hankali.

V.Na'urorin kwantar da iska na sukurori kayan aiki ne na masana'antu.

Ya kamata a lura da waɗannan abubuwan yayin aiki:

1. Kada a ajiye kayan da ke iya kama da wuta ko fashewa kusa da kayan aikin. Haka kuma, a tabbatar cewa iskar ba ta toshe ba yayin aiki.

2. Ana matse bututun ruwa; kar a sassauta matosai ko bawuloli na bututu, kamar tarkon tururi da magudanar ruwa.

3. A riƙa duba yawan amfani da man shafawa akai-akai. Idan man ya yi ƙasa kuma yana ƙaruwa a hankali, a kashe injin. A sake cika man shafawa idan injin ba ya buƙatar matsi.

4. A riƙa duba tarkon tururi na atomatik na na'urar compressor ta sikirin don ganin yadda ake aiki da kyau don hana danshi shiga tsarin.

5. A zubar da tankunan mai da iskar gas a duk mako. Dole ne na'urar ta yi aiki na tsawon akalla awanni 2 a mako.

6. A lokacin duba aiki na yau da kullun, tabbatar da cewa maɓallin matsi da shirin kula da kullewa suna aiki yadda ya kamata. Aikin injina mara kyau yana ƙara yawan amfani da makamashi kuma, a cikin mawuyacin hali, na iya haifar da ƙonewar injin.

7. Idan akwai ƙara ko girgiza da ba a saba gani ba yayin aiki, a kashe na'urar nan da nan don a duba ta.

8. Dole ne matsin lamba na aikin damfarar iska ya kasance daidai da matsin lambar da aka nuna akan lakabin suna don tabbatar da ingantaccen aiki da rage amfani da makamashi.

OPPAIR na neman wakilan duniya, barka da zuwa tuntuɓar mu don tambayoyi: WhatsApp: +86 14768192555

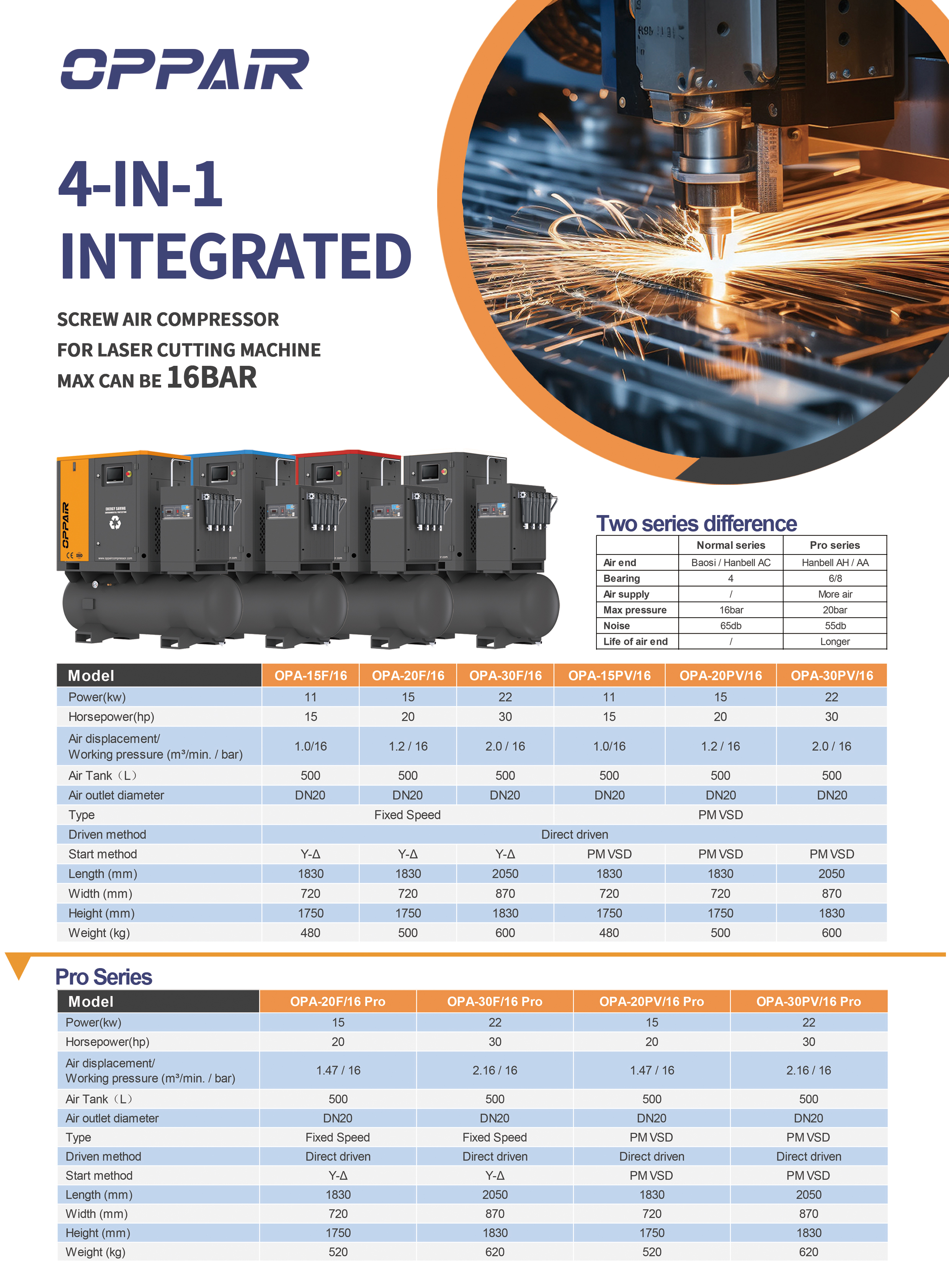

#PM VSD & Na'urar Kwamfutar Iska Mai Sauri #Mai amfani da na'urar yankewa ta Laser 4-IN-1/5-IN-1/Skid da aka ɗora #Mai kwamfuta mataki biyu #3-5bar jerin ƙarancin matsi #Mai Kwamfuta Mara Mai #Mai Kwamfutar Wayar hannu ta Diesel #Mai Jana'izar Nitrogen #Mai Bugawa

#Mai kunna iska mai juyawa #Mai kunna iska mai juyawa tare da na'urar busar da iska #Sukurin Matsi Mai Ƙarancin Hayaniya Mai Mataki Biyu na Iska Mai Matsi#Kwamfutocin iska guda ɗaya na sukurori#Skid saka Laser yanke sukurori iska kwampreso#mai sanyaya dunƙule iska kwampreso

Lokacin Saƙo: Satumba-28-2025